Precision & Compliance

In the Solar Industry, the mantra of “getting it right the first time” has never been more critical.

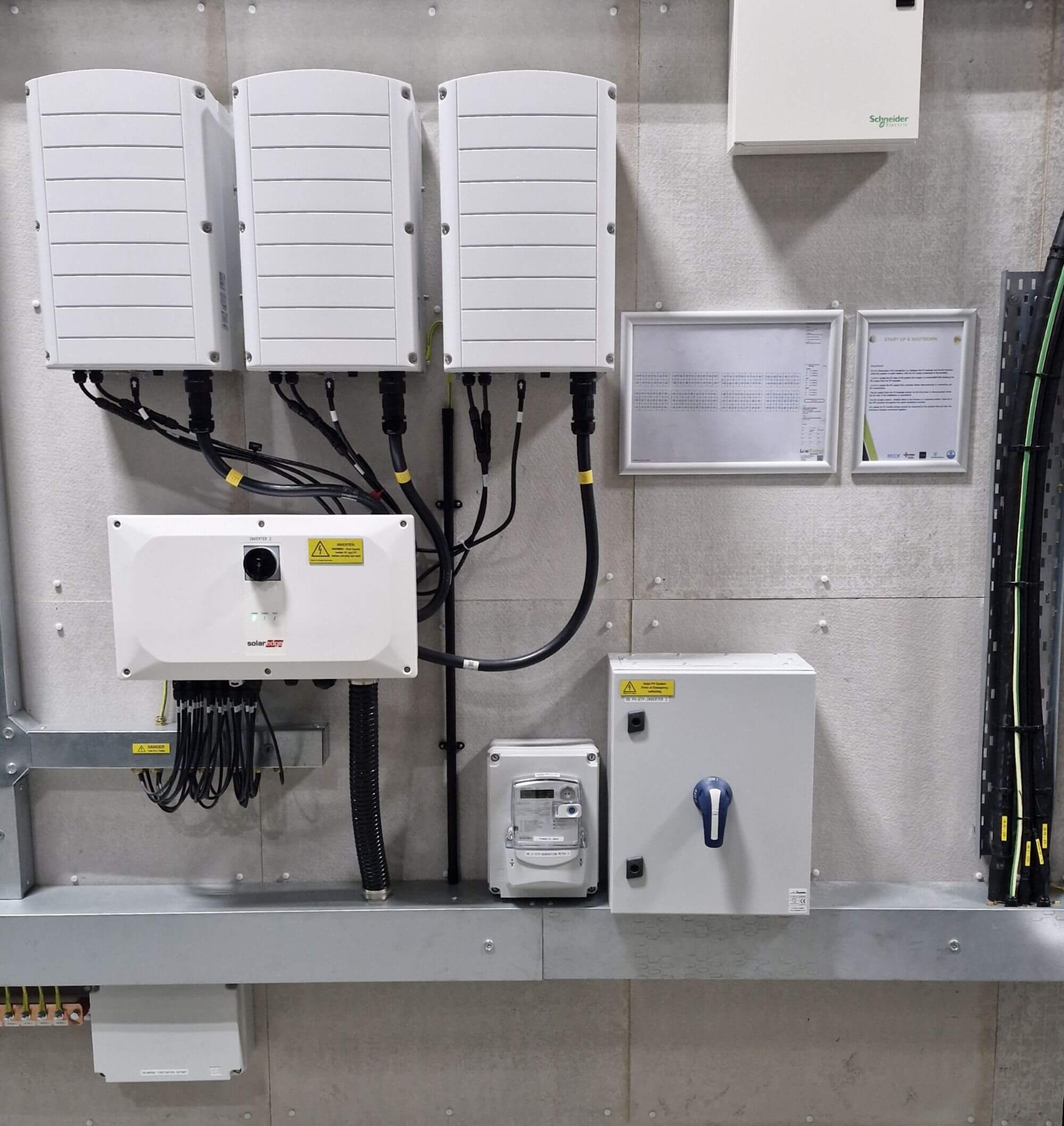

At Low Energy Services, our commitment to delivering quality solar installations extends far beyond simply installing a system; it encompasses the absolute quality, longevity, and structural integrity of every component we fix to a businesses roof. This dedication to best practices is non-negotiable for us and it is why we are continually investing in cutting-edge assembly tools that guarantee a compliant and traceable installation process.

The Silent Threat: Why Impact Drivers Don’t Belong on Your Roof

The installation of a roof-mounted system, whether it’s for solar panels or other low energy services components, requires a meticulous approach to fastening. The bolts, clamps and fixings that hold the system in place are the foundation of its durability and wind load resistance.

A fundamental and often overlooked rule, explicitly stated in virtually all mounting system manufacturers’ instructions, is the exclusion of impact drivers. Yet, shockingly, many installation companies still rely on these tools.

The Risk of Non-Compliance

An impact driver is designed for speed and brute force, not precision. They deliver a series of rotational impacts to tighten a fastener. While this is fast, it comes with a host of severe risks for critical applications like roof mounting:

Over-Torquing and Material Damage: Impact drivers make it almost impossible for an installer to gauge the applied torque. Exceeding the manufacturer’s specified torque can range from as low as 8 Nm (70 in-lbs) up to 40 Nm (350 in-lbs) depending on the bolt size (M6, M8, M10), material, and mounting type. This can have catastrophic consequences. It can cause galling (where stainless steel fasteners weld together), making removal impossible without breakage. It can also cause component deformation, which stresses or permanently damages the aluminium or steel components of the mounting system and the fragile frames of PV modules. Furthermore, it can lead to thread stripping, severely compromising the mechanical connection and leading to premature failure.

Under-Torquing and System Failure: Conversely, an impact driver can easily result in an under-torqued connection, especially with a low or failing battery. An under-tightened bolt will loosen over time due to environmental factors like wind uplift and vibration, causing the connection to slacken and increasing the risk of mechanical failure. An unsecured mounting system is a safety hazard, particularly in areas prone to high winds or heavy snow load.

By using impact drivers, companies are knowingly voiding the mounting system manufacturer’s warranty and, more importantly, jeopardising the long-term reliability and structural integrity of your investment. This is a lapse in quality control that our inhouse team will simply not tolerate.

Innovation in Action

The Ingersoll Rand QX Connect Series

For years, we have prioritised quality assurance by employing tools that allow for controlled fastening, starting with our reliable Ingersoll Rand torque drills. As our company has grown, our commitment to being an industry leader in installation quality has driven a significant investment in the latest technology – the Ingersoll Rand QX Connect Cordless Assembly Tools, sourced from our trusted partner, Applied Torque of Glasgow.

This is more than just a new piece of equipment; it is an Intelligent Cordless Assembly Tool that revolutionises the fastening process for our highly critical fastening applications on your roof.

Achieving Traceable Precision

The core advantage of the QX Connect Series is its transducerized technology. A transducerized tool contains an internal sensor that measures the actual applied torque and angle in real-time, offering a level of accuracy and traceability unmatched by standard clutch-based tools.

We can configure and control up to 32 programmable configurations on a single tool. This means that for the key mounting system manufacturers we use, the exact specified torque level is pre-programmed for each bolt type.

A visual indicator on the rear of the drill provides a clear and instant indication that the required torque level has been achieved. If the level is missed, a red light immediately flags an issue, ensuring no non-compliant fastenings leave the site uncorrected. For the highest level of quality control, these tools provide accurate and traceable results for every single bolted connection. This end-of-run data can be recorded, archived, and wirelessly communicated, forming a complete digital record of the assembly process. This is the ultimate proof of a safe and compliant installation.

The investment in the QX Connect Series is a strategic move to increase productivity, improve controls, and enhance ergonomics for our highly skilled inhouse solar installers. We understand that people are our greatest asset, and providing the best tools for the job is paramount to maintaining a high standard of work and a safe working environment.

The Low Energy Services Guarantee

Choosing Low Energy Services means choosing a company where quality control is integrated into every stage of the process, especially the critical fastening applications that ensure the security and longevity of your investment.

Investing Ingersoll Rand QX Connect Series is a clear statement that we are not content with industry norms that rely on non-compliant, imprecise tools like impact drivers. We believe in adhering strictly to every mounting manufacturer’s instruction and using transducerized tools for precise torque measurement that provides a digital record for full quality assurance.

This allows us to build systems that are designed to last, thanks to perfectly tensioned, non-stressed components.

When you invest in low energy services with us, you are investing in peace of mind, knowing that every bolt on your roof has been tightened to the exact specification, ensuring a safe and compliant installation for decades to come. Contact us today to discuss your next solar PV or low energy installation project and discover how our commitment to intelligent cordless assembly tools ensures the durability and performance of your system.

Renewable Energy Specialists

Renewable Energy Specialists